Your Reliable Partner for Mass Transfer Equipment

15+

YEARS OF WORKING EXPERIENCE IN THIS FIELD

WELCOME TO KUBER PRECISION TECHNOLOGY

Delivering High-Quality Mass Transfer Equipment Globally

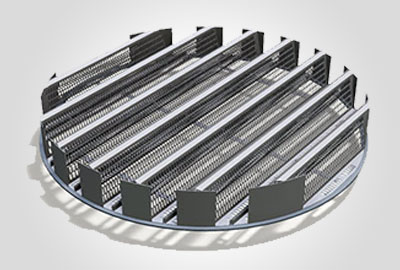

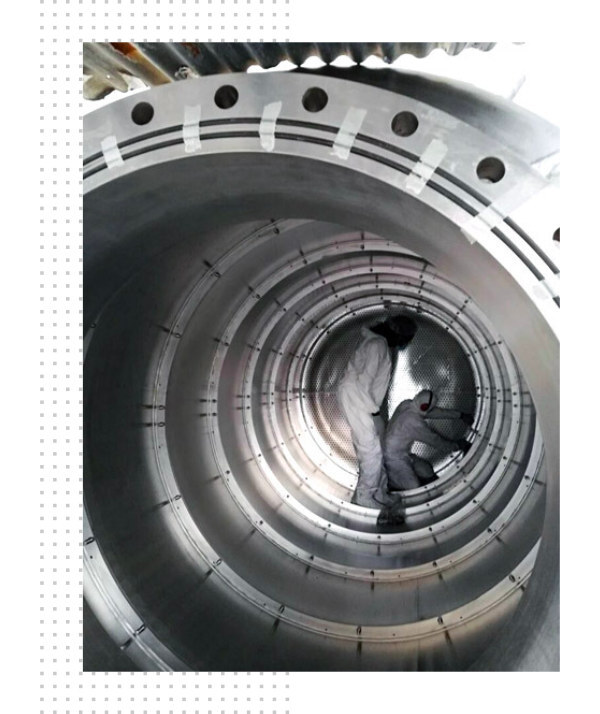

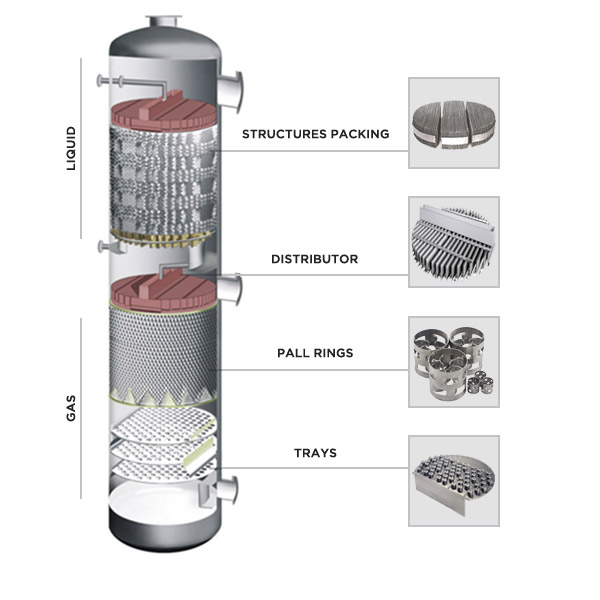

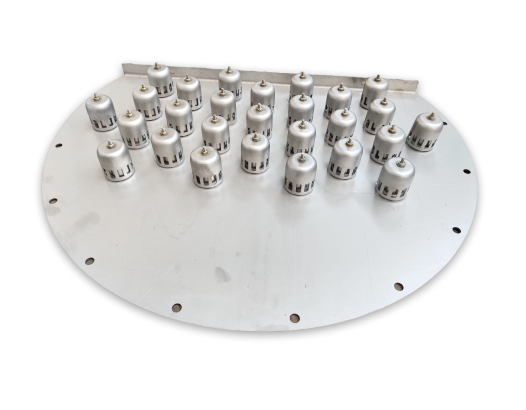

Kuber Precision Technology is amongst one of the most reputed manufacturer and supplier companies of column internals in India. It has a dedicated mass transfer group that designs, manufactures, and supplies column packings and associated column internals for critical applications. In any column system, packings can give an ideal presentation just when complemented with appropriately designed tower distributors, authorities, collectors, supports, and other column internals for optimum liquid–vapor distribution to the packed beds. KPT has a wide range of column internals which include liquid/vapour distributors, collector trays, and packing support & many more.

We Provide High-Quality Product

FAQ'S

Our Mass transfer technology is used extensively in different industries like:

- Food and Beverages

- Chemical industry

- Water and Waste-Water Treatment

- Packaging

- Water Treatment

- Pharmaceuticals

- Oil and Gas

- Pulp and Paper